Control method of withdrawal terminal

1. The terminal is not assembled in the rubber core and the needle is pulled out

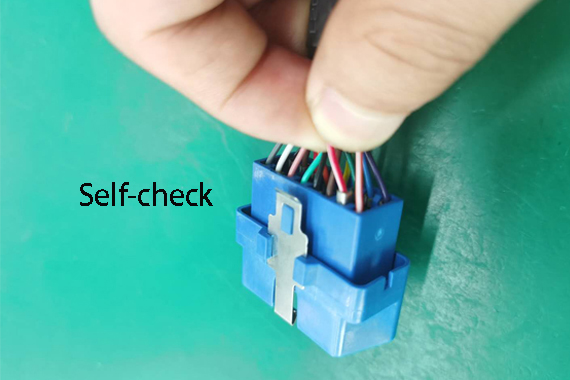

The terminal is not assembled in place in the rubber core. Intuitively speaking, it is the employee's operation error, which caused the outflow of non-conforming products. In the current wire harness manufacturing industry, terminal assembly basically relies on manual operations. The commonly recognized terminal insertion method in the wire harness industry is "one plug, two listen, three pull". The most important thing is "three-return pull". The effectiveness of the pull-back action determines the first pass rate of the withdrawal terminal. The staff's operational proficiency determines the effectiveness of the pullback action. Therefore, employees need to self-check during assembly work. The same IPQC also needs to conduct random inspections.

2. When the rubber core and the rubber core are inserted, the terminal is ejected or forced to exit

When the rubber core and the rubber core are mated, the terminal is pushed out or the core wire is forced to cause the terminal to exit. It shows that there are errors in the design process of the rubber core, and the engineering needs to check the drawings and whether there are problems in the mold manufacturing process.

3. Stuck point lack of material leads to withdrawal of the needle

No abnormalities were found in the first two points. Just check the rubber core itself. Check whether the rubber core itself is intact, whether there is insufficient material or stuck spots in the rubber core.

Yeahui is a connector supplier with 13 years of experience in developing high-quality connectors and wiring harnesses. We have many types of products, including obd connector, circular connector, agricultural connector and so on. We can meet the requirements of various customers. Feel free to learn more about connectors or buy our connectors, looking forward to your message.

More about NEWS(Reasons for connector terminal withdrawal).

评论

发表评论