Definition and test of harness waterproof grade

Harness waterproofing is necessary and necessary in the work of harnesses. Check the reliability of the waterproof design. Next, I will briefly introduce the definition and test method of the waterproof grade of the automobile wiring harness.

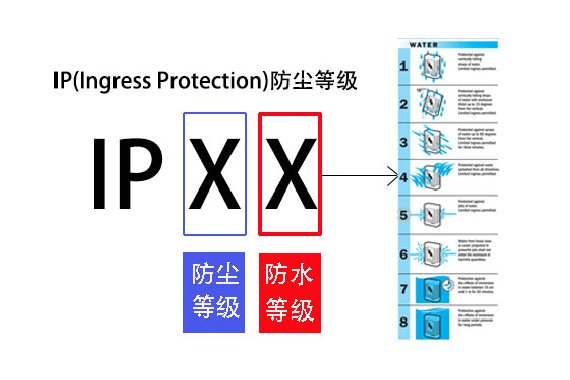

Our common expression is IPXX or something. Both IP and the following two digits have a certain meaning. The IP (INGRESS PROTECTION) protection level system was drafted by the IEC (INTERNATIONALELECTROTECHNICALCOMMISSION) to classify electrical appliances according to their dust and moisture resistance characteristics. The IP protection level is composed of two numbers. The first number indicates the level of dustproofness and protection against the intrusion of foreign objects. In order to avoid an electric shock), the second number indicates the sealing degree of the appliance against moisture and water immersion, and the larger the number, the higher the protection level.

The protection level is mostly expressed by IP followed by two numbers, and the number is used to clarify the protection level.

The first digit indicates the range of the equipment's resistance to fine dust or the degree to which people are protected from harm in a sealed environment. Represents the level to prevent the entry of solid foreign objects, the highest level is 6;

The second digit indicates how waterproof the device is. Represents the level of preventing water ingress, the highest level is 8.

For example, the protection grade of the motor is IP65. Contact electrical equipment protection and foreign object protection level (first number) Electrical equipment waterproof protection level (second number)

IP dustproof rating (the first X indicates)

0: No protection

1: Prevent large solids from intruding

2: Prevent the invasion of medium-sized solids

3: Prevent intrusion of small solids

4: Prevent solid objects larger than 1mm from entering

5: Prevent harmful dust accumulation

6: Completely prevent dust from entering

Because the general wiring harness has high requirements for dust prevention, we default to 6, which is why we often use IP6X to indicate the waterproof level of the wiring harness on the supplier's report or drawing.

IP waterproof rating range

The waterproof test includes the second characteristic number from 1 to 8, that is, the protection grade code is IPX1 to IPX8.

No protection No special protection

1 Prevent dripping water from entering

2 Prevent drip intrusion when tilted at 15 degrees

3 Prevent the intrusion of sprayed water

4 Prevent splashing water intrusion from all directions

5 Prevent the intrusion of large waves of water

6 Prevent large waves of water from invading Electrical equipment invading water for a certain period of time or water pressure can still ensure the normal operation of the equipment

7 Prevent intrusion of intrusive water Indefinite submerged water in electrical equipment can ensure the normal operation of the equipment under certain water pressure

8 Prevent sunken effects

IP protection grade waterproof

(1) IPX 1

Method name: Vertical drip test

Test equipment: drip test device

Sample placement: placed on the rotating sample table at 1r / min according to the normal working position of the sample, the distance from the top of the sample to the drip port is not more than 200mm

Test condition: the drip volume is 1.0 ± 0.5mm / min

Duration: 10 min

(2) IPX 2

Method name: tilting 15 ° drip test

Test equipment: drip test device

Sample placement: Make a surface of the sample at an angle of 15 ° to the vertical, and the distance from the top of the sample to the drip port should not exceed 200mm. After each test, change the other side for a total of four times.

Test condition: the drip volume is 3.0 ± 0.5 mm / min

Duration: 4 × 2.5 min (total 10 min)

(3) IPX 3

Method name: water spray test

experiment method:

a. Swing tube type water spray test

Test equipment: pendulum tube spray test device

Sample placement: Select a swing tube of an appropriate radius so that the height of the sample table is at the diameter of the swing tube. Place the sample on the sample table so that the distance from the top of the sample to the sample spout is not greater than 200mm, and the sample table does not rotate.

Test conditions: The water flow rate is calculated according to the number of spray holes of the pendulum tube, each hole is 0.07 L / min. When water is sprayed, the water spray holes in the 60 ° arcs on both sides of the pendulum tube are sprayed toward the sample. The test sample is placed in the center of the semicircle of the pendulum tube. The pendulum tube oscillates 60 ° on both sides of the vertical line for a total of 120 °. Each swing (2 × 120 °) about 4s

Test time: continuous watering for 10 min

b. Sprinkler test

Test equipment: hand-held water splash test device

Sample placement: make the parallel distance between the top of the test and the nozzle of the hand nozzle between 300mm and 500mm

Test conditions: a baffle with a counterweight should be installed during the test, with a water flow of 10 L / min

Test time: calculated according to the surface area of the tested sample shell, 1 min per square meter (excluding installation area), at least 5 min

(4) IPX 4

Method name: Water splash test

experiment method:

a. Swing tube splash test

Test equipment and sample placement: the same as paragraph a of IPX 3 above;

Test conditions: Except for the conditions described below, they are the same as paragraph a of IPX 3 above; the water spray area is the water spray holes in the spray holes in the 90 ° arcs on both sides of the center point of the swing tube. The test sample is placed in the center of the semicircle of the pendulum tube. The pendulum tube swings 180 ° on both sides of the vertical line for a total of about 360 °. Each swing (2 × 360 °) is about 12s

Test time: the same as paragraph a of IPX 3 above (ie 10 min).

b. Sprinkler test

Test equipment and sample placement: the same as paragraph b of IPX 3 above;

Test conditions: Remove the baffle with balance weight installed on the equipment, and the rest is the same as the above b of IPX 3;

Test time: the same as paragraph b of the above IPX 3, that is, calculated according to the surface area of the shell of the tested sample, 1 min per square meter (excluding installation area) at least 5 min

(5) IPX 5

Method name: water spray test

Test equipment: the inner diameter of the nozzle is 6.3mm

Test conditions: The distance between the test sample and the water spout is 2.5m ~ 3m, and the water flow is 12.5 L / min (750 L / h)

Test time: calculated according to the surface area of the tested sample shell, 1 min per square meter (excluding the installation area), at least 3 min

(6) IPX 6

Method name: Strong water spray test;

Test equipment: the inner diameter of the nozzle is 12.5 mm

Test conditions: The distance between the test sample and the water spout is 2.5m ~ 3m, and the water flow is 100 L / min (6000 L / h)

Test time: Calculated according to the surface area of the tested sample shell, 1 min per square meter (excluding installation area) at least 3 min

(7) IPX 7

Method name: Short-term immersion test

Test equipment and test conditions: immersion tank. The size should be such that the distance between the bottom of the sample and the water surface is at least 1m after the sample is placed in the immersion tank. The distance from the top of the sample to the water surface is at least 0.15m

Test time: 30 min

(8) IPX 8

Method name: Continuous driving test;

Test equipment, test conditions, and test time: agreed by the supply and demand (sales and purchase) parties, the severity of the test should be higher than IPX 7.

Note: In addition, many outdoor electronic products are also emphasizing floating ability.

(9) 0IPX 9

Method name: high-pressure jet test equipment: nozzle water nozzle

Test equipment: the inner diameter of the nozzle's water jet is 12.5 mm;

Test conditions: spray angle: 0 °, 30 °, 6

Yeahui is a connector supplier with 11 years of experience in developing high-quality connectors and wiring harnesses. We have many types of products, including obd connector, circular connector, agricultural connector, and so on. We can meet the requirements of various customers. Feel free to learn more about connectors or buy our connectors, looking forward to your message.

More about COVID-19(Three options for wire forming materials).

评论

发表评论