How is the cable connected to the connector

Welding: The solder joints are required to be smooth, which need without solder build-up, firm and reliable, and also cannot be poor welding. Poor welding can easily lead to cable assembly failure. There is no good way to detect poor welding currently and can only be guaranteed from a strict process. If the cable core is thin, it should be tinned on the cable core and soldered to the inner conductor of the connector. If the cable core is thicker, more solder is needed for soldering. First, fill the appropriate amount of solder in the wire hole of the inner conductor of the connector, and then heat it with a soldering iron. When the solder melts, insert the inner conductor of the cable into the hole and rotate it left and right or repeatedly insert and remove the inner conductor of the cable so that the inner conductor of the cable is in full contact with the solder in the inner conductor of the connector to ensure reliable soldering and no poor welding. If there is excess solder, it can be scraped off with a blade, taking care not to scratch the plating of the inner conductor of the connector. After soldering, clean the solder on the surface of the inner conductor of the connector and the scraped solder scrap to avoid the influence on its electrical properties. Some connectors are designed with electrical performance and temperature compensated dimensions. Positioning is determined when soldering the inner conductor of the cable to ensure electrical performance of the cable assembly.

Crimp: In order to ensure that the impedance of the cable and the connector are matched, it is required to be crimped with a professional crimping tool, and the precision of the crimping fit is very high. A flexible cable assembly commonly used for low frequencies, using a metal tail sleeve to secure the shield of the cable to the outer conductor of the connector by means of a hexagonal crimp,which need to use crimping tooling, and have requirements for tooling size and pressure. The crimping size should be reasonable, and the crimping edge is required to neither damage the cable nor be reliably crimped.

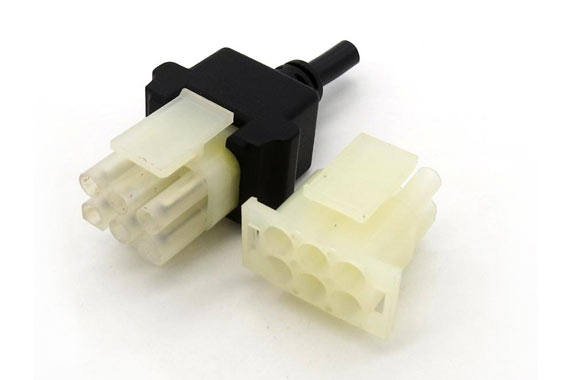

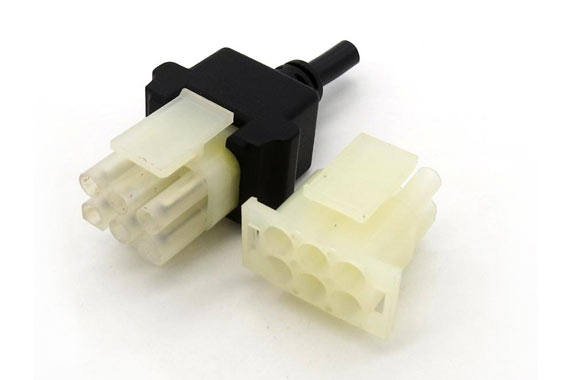

Yeahui is a connector cable supplier with 11 years of experience in developing high quality connectors and wiring harnesses. wo have many types of products, including obd cable, circular connector, agricultural connector and so on.We can meet the requirements of various customers. Feel free to learn more about connectors or buy our connectors,looking forward to your message.

Read more about the connectors(Connector Market Competition Analysis).

评论

发表评论